Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

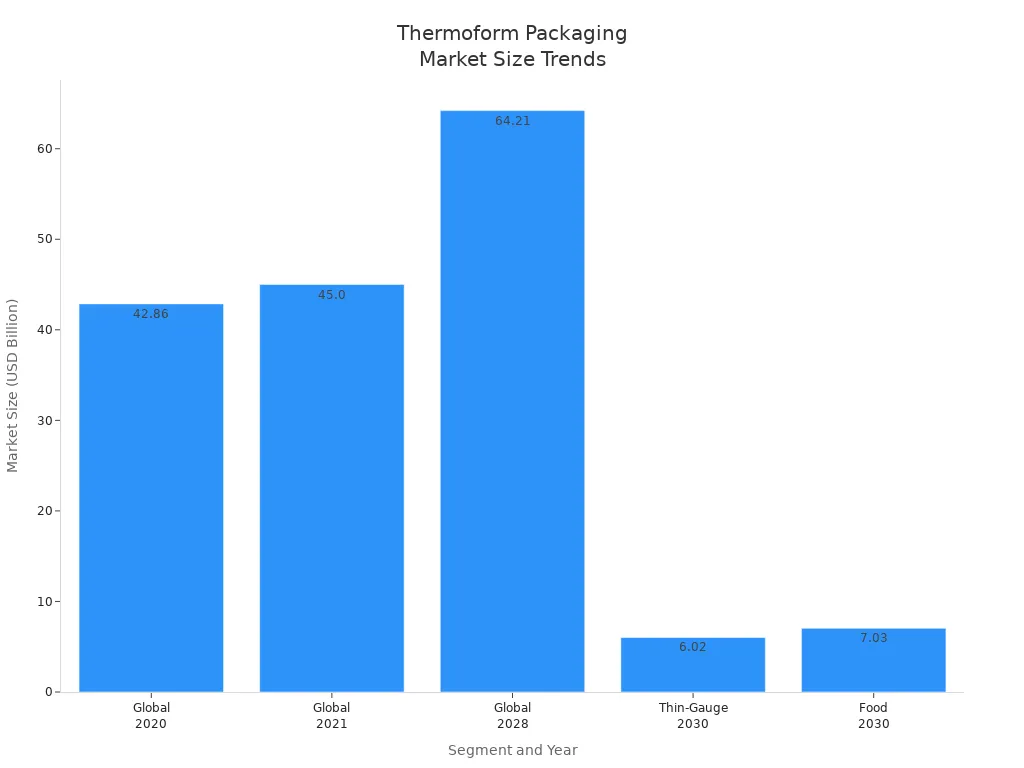

Thin-gauge thermoforming is very important in packaging. It is used most for food, medical, and consumer product packaging. Manufacturers use thin-gauge thermoforming to make trays, clamshells, and containers. These items help keep things safe and easy to use. The global market for thin-gauge thermoforming may reach $6.02 billion by 2030. Food packaging alone could go over $7.03 billion.

Thin-gauge thermoforming is very important in packaging. It is used most for food, medical, and consumer product packaging. Manufacturers use thin-gauge thermoforming to make trays, clamshells, and containers. These items help keep things safe and easy to use. The global market for thin-gauge thermoforming may reach $6.02 billion by 2030. Food packaging alone could go over $7.03 billion.

Thin-gauge materials work well, can be recycled, and are very flexible. The thermoforming process costs less to start and is faster than other ways. Light gauge thermoforming helps the environment and makes products quickly for many industries.

Thin-gauge thermoforming creates strong and light packaging. The packaging can be recycled. It is used for food, medical, and consumer products. This process helps keep food fresh. It keeps medical items safe. It protects goods during shipping and display. Thin-gauge thermoforming is fast and saves money. Companies can make custom packaging quickly. Clear and special-shaped packages help people see products better. These packages make brands look better. They help customers trust and pick products. Thin-gauge thermoforming uses less plastic. It uses machines that save energy. This helps make eco-friendly packaging. It also helps cut down on waste.

Thin-gauge thermoforming is used a lot for food packaging. It makes many types of disposable or semi-disposable items. This process creates clamshells, blister packs, trays, and containers. These are very important for the food service industry. Thin-gauge thermoforming is fast and saves money. Companies can make light packaging quickly. This packaging keeps food safe and fresh.

Thin-gauge thermoforming is strong in the market. In 2021, it made up over 31.1% of packaging revenue. Food packaging made up more than 41.1%. This shows thin-gauge solutions are very important for food.

| Segment | Revenue Share 2021 |

|---|---|

| Thin-gauge thermoforming | >31.1% |

| Food packaging application | >41.1% |

Vacuum forming and pressure forming shape thin-gauge materials. These methods help make custom designs for each product. Custom shapes keep food safe from water and germs. They also help products look nice in stores. Features like tamper-evident seals, venting, and clear lids make packaging better and easier to use.

Thin-gauge thermoforming is used for many food items. It makes trays, cups, plates, bowls, and food containers. These are popular because they are light, recyclable, and simple to use.

Some common products made with thin-gauge thermoforming are:

Clamshells for sandwiches and salads

Blister packs for snacks and candy

Custom trays for bakery goods

Pick and place packaging for ready meals

Vacuum forming and pressure forming help make packaging that fits food well. This fit keeps food safe when moving and helps it last longer. Clear containers let people see the food, which builds trust. Light gauge thermoforming also helps brands by allowing good printing and special shapes.

Thin-gauge thermoforming gives the food industry a safe and good way to make packaging. It is flexible and works fast, so it is the best choice for many food packaging needs.

Thin gauge thermoforming is very important in healthcare. Hospitals and clinics need safe packaging for medical items. This packaging keeps things like syringes and pills clean. It also protects medical devices from germs and water. Thin-gauge thermoforming makes special packaging for each item. This helps keep products safe and fresh for patients.

Medical trays and packages made with thin-gauge materials stop germs. These packages use PET, APET, PETG, and HIPS plastics. These plastics are strong and clear. They do not break easily. Workers can see what is inside the package. This helps them know what they are using and keeps everyone safe.

Common products made with thin gauge thermoforming are:

Blister packs for pills and capsules

Medical trays

Clamshells for medical tools

Plastic lids and inserts

More people need these products as healthcare grows. This is happening a lot in the USA and Canada.

Thin gauge thermoforming has many good points for healthcare. It uses special plastics that work with cleaning methods. These methods include ethylene oxide and gamma rays. Factories make these packages in clean rooms. This keeps the packages free from germs. Custom shapes stop devices from moving or breaking.

The process also follows strict safety rules. Companies use FDA-approved plastics like HDPE, PET, and PP. They follow Good Manufacturing Practices. They keep track of all materials. They check quality, test the process, and train workers. This makes sure every package is safe and meets high standards.

| Material | Barrier Focus | Key Properties and Uses |

|---|---|---|

| PETG | Chemical, Sterile | Strong, clear, resists chemicals, good for sterilization |

| EVOH | Oxygen | Blocks oxygen, keeps products fresh |

| PCTFE | Moisture | Stops moisture, used in blister packs |

Thin-gauge thermoforming also makes packaging fit just right. The process uses special tools to make sure each tray fits. This keeps medical devices and medicine safe. The result is safe, strong, and low-cost packaging for healthcare.

Thin gauge thermoforming is important for making packaging. Companies use it for electronics, toys, and hardware. It also works for many other products. The process shapes plastic sheets into trays and clamshells. It also makes blister packs and strong containers. These packages keep products safe during shipping and in stores. Thin gauge thermoforming uses plastic sheets under 0.060 inches thick. This makes the process fast and keeps costs low. Factories can make a lot of packages quickly. This is good for making many products at once.

Some common uses are:

Clamshell packaging for electronics and toys

Blister packs for small goods

Anti-static trays for electronic parts

Candy trays and cosmetics packaging

Thin gauge thermoforming is used more than other methods. In 2023, it made over 35% of the market’s revenue. People like it because it saves money and works well. It is also easy to recycle.

Thermoforming has many good points for brands and shoppers. Clear plastics like PET let people see what is inside. This helps customers trust the product and makes it look nice. Special shapes and designs help brands stand out in stores. Companies can add logos and product details to the packaging. This makes it easier for people to find and pick their products.

Thermoforming makes packaging that is strong and not too costly. Light packages cost less to ship and are easy to carry. Good packaging keeps products safe from damage in stores and during shipping.

| Benefit | Description |

|---|---|

| Product Visibility | Clear packaging lets shoppers see the product, boosting confidence |

| Custom Branding | Unique shapes and printed details help brands attract attention |

| Protection | Durable containers prevent damage during shipping and handling |

| Efficiency | Fast production and low material waste support high-volume needs |

| Sustainability | Use of recyclable materials and energy-efficient processes reduces impact |

Brands use custom thermoforming to make special packaging. This helps their products fit just right. It also lets them keep up with new trends and sell new items faster. Many companies pick thin-gauge materials because they are easy to recycle and use less plastic. Better machines and automation help lower costs and make things faster.

Thin gauge thermoforming gives today’s consumer goods industries what they need. It makes packaging that is fast, looks good, and is better for the planet.

Thin-gauge thermoforming is changing how we package things. It is used for food, healthcare, and many products. This process makes packages that are light and easy to recycle. These packages help cut down on waste and help the planet. People now use more eco-friendly plastics and better machines. Automation helps make packaging faster and better. Companies keep making new materials and designs to fit what people want. Thermoforming is a good choice for safe and smart packaging.

New technology and caring for the planet help make packaging better.

People want packaging that is good for the earth and easy to use. This helps the industry grow.

Thin-gauge thermoforming shapes thin plastic sheets. These sheets are less than 0.060 inches thick. The process uses heat and molds to form containers. It makes packaging for food, medical, and other products. The containers are strong and light.

Thin-gauge thermoforming uses less plastic than other ways. Many packages made this way can be recycled. Factories use machines that save energy. These things help lower waste and protect the earth.

Factories use plastics like PET, PETG, HIPS, and PP. These plastics are strong and clear. They are safe for food and medical items. Some plastics keep out water and air to keep things fresh.

Companies like thin-gauge thermoforming because it is fast and saves money. The process makes special shapes for each product. It helps brands show their products and keep them safe.

Yes, thin-gauge thermoforming makes trays, clamshells, and blister packs. These packages keep medical tools and medicine clean. They also protect them from germs and damage.