Views: 0 Author: Site Editor Publish Time: 2025-10-11 Origin: Site

You use a thermoforming machine to shape plastic sheets by following a step-by-step process. First, you heat the plastic until it becomes flexible. Next, you form the sheet over a mold with a vacuum that pulls it tightly into shape. Then, you cool the formed part so it keeps its structure. Finally, you trim and finish the product. Each step in the thermoforming process helps create strong and precise shapes.

Thermoforming machines change plastic sheets by heating, shaping, cooling, and cutting. Each step is important to make strong and exact products.

The heating system is very important. It makes the plastic soft so it can bend. Different plastics need different heat levels for the best results.

A vacuum system takes air out from between the mold and the plastic sheet. This helps the sheet fit the mold just right. It makes detailed shapes.

Cooling the shaped plastic is needed. It makes the shape hard and stops it from bending. Cooling quickly can help make more products faster.

Taking care of the thermoforming machine is very important. Clean the parts, look for clogs, and check the settings. This helps stop problems during production.

You need many parts to run a thermoforming machine. Each part helps shape plastic sheets into finished items. These parts work together to make strong and accurate products for factories.

The clamping device keeps the plastic sheet still while heating and forming. You use a clamp frame so the sheet does not move. This helps heat the sheet evenly and makes sure it molds right. If the sheet moves, it can cause bad shapes or mistakes.

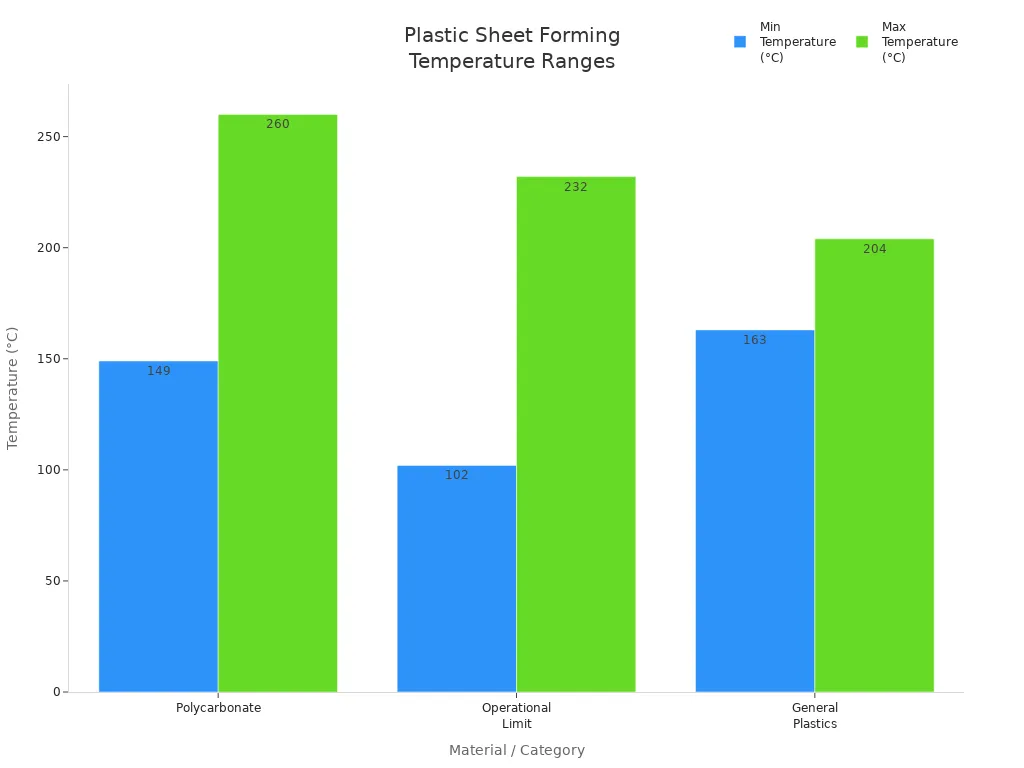

You must heat the plastic sheet before shaping it. The heating system uses radiant heaters, infrared heaters, or convection ovens. These make the sheet soft and bendable. Different plastics need different heat levels. For example, polycarbonate needs 300°F to 500°F (149°C to 260°C). Most plastics heat up between 325°F and 400°F (163°C to 204°C).

| Material | Temperature Range (°F) | Temperature Range (°C) |

|---|---|---|

| Polycarbonate | 300 - 500 | 149 - 260 |

| Operational Limit | 215 - 450 | 102 - 232 |

| General Plastics | 325 - 400 | 163 - 204 |

You can compare how plastics need different forming temperatures:

Heating systems use conduction, convection, and radiation to move heat. You pick the best way based on the plastic and the product you want.

The vacuum system shapes the hot sheet over the mold. You use a vacuum pump to suck out air between the sheet and mold. Air pressure pushes the sheet down to fit the mold. This step helps you make detailed and exact shapes.

The vacuum pump pulls out air between the sheet and mold.

Air pressure pushes the hot sheet onto the mold.

The sheet matches the mold’s shape for good results.

You use the pneumatic system to move air during forming. Pressurized air blows up the hot sheet into the mold. This changes wall thickness and product quality. If air gets stuck, the sheet may stretch unevenly or get thin spots.

| Role of Pneumatic System | Effect on Forming Process |

|---|---|

| Inflates heated plastic sheet into the mold | Changes wall thickness and quality |

| Pressurized air flow through inlet nozzles | Helps the sheet bend better |

| Air trapped between sheet and mold | Causes uneven stretching and thin spots |

After shaping, you must cool the product fast and evenly. Cooling devices use liquid, air, or both. Fast cooling makes more products in less time. Good cooling stops warping and gives a smooth finish.

| Cooling Method | Speed of Cooling | Impact on Production Efficiency | Impact on Product Quality |

|---|---|---|---|

| Liquid Cooling Systems | Faster | Makes more products quickly | Stops surface problems, makes products last longer |

| Air Circulation Cooling | Slower | Saves energy, good for thick parts | May cause rough textures if not done right |

| Combination Systems | Best | Balances speed and energy use | Makes products look and work better |

Better efficiency lets you make more products faster.

Good quality stops mistakes and makes products look nice.

Strong products last longer after they are made.

You use the demoulding device to take the finished item out of the mold. This device may use vacuum holes, blowing air, or mechanical jacks. Each way helps you remove the product without breaking it.

| Mechanism | Description |

|---|---|

| Vacuum attraction holes | These holes use suction to pull the product off the mold. |

| Blowing air | Air blows in the other direction to help release the product. |

| Mechanical jacking/shock | These push or shake the product out of the mold. |

The control system is like the brain of the thermoforming machine. You set temperature, time, and pressure. The system uses smart technology like PLCs to run each step. It keeps everything correct and steady, making better products and faster work.

Tip: New thermoforming machines use computer control systems. These systems run heating, shaping, cooling, and trimming by themselves. You get more exact results and quicker production.

Sensors and feedback loops watch and change settings.

Closed-loop systems change things automatically based on heat or force.

Safety features keep you safe from overheating and other dangers.

Easy designs help you use the machine and make fewer mistakes.

You can see how every part of a thermoforming machine works together. The clamping device holds the sheet, the heating system softens it, the vacuum and pneumatic systems shape it, the cooling device hardens it, the demoulding device takes it out, and the control system manages everything. All these parts help you make great products for factories.

When you use a thermoforming machine, you follow steps to change thin plastic sheets into good products. Each step helps you shape, cool, and take out the finished part. Let’s look at what happens in each stage.

First, you put the plastic sheet into the thermoforming equipment. The clamping device holds the sheet tight so it stays still. This keeps the sheet flat and ready for heating. If the sheet is not even, you might have problems when forming. Always check the sheet to make sure it is the same thickness.

Tip: Thin plastic sheets with even thickness help you avoid problems and make the process easier.

Next, you heat the plastic sheet until it gets soft and bends easily. The heating system uses radiant or infrared heaters to warm the sheet. You must set the right temperature for your plastic. For example:

ABS sheets need 300-350°F (150-177°C).

Polycarbonate sheets need 300-500°F (149-260°C).

Most plastics heat up between 325-400°F (163-204°C).

You keep the sheet in the heating area until it is bendable. If you heat the sheet unevenly, you might get thin or thick spots. You can change the heating speed or use a heat shield to fix heating problems.

After heating, you move the soft sheet over the mold. This is called forming. You use vacuum or pressure to shape the sheet. Here’s what you do:

Put the hot sheet over the mold.

Use vacuum pressure to pull air out of the mold. This makes the sheet fit the mold’s shape.

Vacuum pressure is usually 70–85 kPa (20–25 inHg). This helps you get exact shapes.

In pressure forming, you use both vacuum and air pressure. This lets you make detailed designs.

If the vacuum system does not work, clean the vacuum holes or use a stronger pump. Good forming needs strong vacuum and even air pressure.

Once the sheet takes the mold’s shape, you need to cool it. Cooling makes the part hard and strong. You can use air, water, or both. Cooling time depends on the material and your tool design. Water-cooled aluminum tools can cool parts much faster than other tools. Fast cooling helps you make more products quickly.

If cooling does not work well, check for blockages or change your cooling system. Good cooling stops warping and keeps your product smooth.

The last step is demoulding. You take the finished part out of the mold without breaking it. You can use vacuum holes, blowing air, or mechanical jacks. To stop damage, follow these best practices:

| Best Practice | Description |

|---|---|

| Use Mold Release Agents | These agents help the part come out easier. |

| Adjust Cooling and Ejection Force | Change cooling time and force to stop damage. |

| Do Regular Maintenance | Check and fix worn parts for smooth work. |

| Use Good Draft Angles | Use at least 1°–2° draft per side for easy release. |

| Treat Mold Surface | Use coatings to lower friction and sticking. |

| Improve Mold Design | Add strong ejection and good venting. |

| Pick Easy Demolding Materials | Use thermoplastics like polypropylene for easy removal. |

| Control Cooling | Cool evenly and enough before taking out the part. |

If you follow these steps, you can remove the product safely and keep its shape. You finish by trimming and fixing the edges. This gives you good plastic products ready for use.

Note: Every step in the thermoforming process works together to help you make strong and accurate products. If you have problems, you can change machine settings or improve your mold.

| Step | Description |

|---|---|

| 1 | Put the plastic sheet into the machine. |

| 2 | Heat the sheet at higher temperatures. |

| 3 | Move the sheet into the mold. |

| 4 | Use vacuum to shape the sheet. |

| 5 | Cool the part until it is hard. |

| 6 | Check quality and trim the part. |

| 7 | Fix the edges of the part. |

You can see how thermoforming machines help you turn plastic sheets into finished products. Each stage is important for making strong and reliable items.

You can pick from different thermoforming machines. Each type shapes plastic sheets in its own way. Let’s learn about the main types and how they work.

Vacuum forming is the most popular method. You heat a plastic sheet until it gets soft. Then, you use a vacuum to pull the sheet over a mold. This helps you make simple shapes fast and cheaply.

Tip: Vacuum forming is good for making lots of products quickly.

Here is a table that compares vacuum forming to other machines:

| Machine Type | Production Speed | Cost Efficiency |

|---|---|---|

| Vacuum Forming | High | Very High |

| Pressure Forming | Low | Moderate |

| Blister Forming | Moderate | High |

Vacuum forming machines make products for many industries:

Automotive: dashboards and door panels

Medical: trays and equipment housings

Aerospace: lightweight interior parts

Consumer goods: packaging and parts

Retail: custom displays and signs

You get benefits like cheaper tools, quick design changes, and less waste. You can also recycle leftover plastic.

Pressure forming uses both vacuum and air pressure. This shapes the heated plastic sheet. You get sharper details and more complex shapes than with vacuum forming. You can make products with deep textures and smooth finishes.

| Feature | Pressure Forming | Vacuum Forming |

|---|---|---|

| Process | Uses air pressure to shape material | Uses suction to shape material |

| Product Quality | Higher quality with sharp details | Simpler shapes with less detail |

| Complexity of Shapes | Can make tricky parts and undercuts | Limited to easier shapes |

You use pressure forming for high-quality parts. These are for medical devices, electronics, or special packaging. This method makes detailed products, but it can take longer and cost more.

Mechanical forming uses moving parts like plugs or jacks. These stretch and shape the plastic sheet over the mold. You get strong and accurate products with this method. Mechanical forming is good for quick prototypes and design changes.

You can use many kinds of plastic.

You finish setting up tools in just a few weeks.

You can react fast to market changes and tight deadlines.

Mechanical forming helps you make products for consumer goods, cars, and medical items. You get fast production and flexible design choices.

Note: Pick the right thermoforming machine based on your product, speed, and budget.

| Type of Machine | Mechanism Description |

|---|---|

| Vacuum Forming Machine | Uses a vacuum to pull a heated plastic sheet into a mold. |

| Pressure Forming Machine | Uses vacuum and air pressure to make complex shapes and details. |

| Mechanical Forming Machine | Uses mechanical force, like plugs or jacks, to stretch and shape the plastic sheet over the mold. |

You can see how different thermoforming machines help you make many kinds of products for factories.

You can watch how every part of a thermoforming machine works together. Each part helps change a plastic sheet into a finished product. The steps are heating, molding, and cooling. These steps decide how good the product will be.

You should look at water lines often. You need to change oil when needed. You must set the oven right so the machine works well.

You can make lots of products in factories. These can be small packages or big items.

Thermoforming lets you use recycled materials. It also helps save energy. This makes it a smart choice for today’s factories.

You can use plastics like ABS, PET, PVC, polycarbonate, and polystyrene. Each plastic needs its own temperature. Always check the sheet’s thickness and type before you start.

You clean the machine by wiping it and removing dust. You look at water lines and change oil often. You check heaters and vacuum pumps for damage. Taking care of the machine helps it last longer.

Yes, you can recycle scrap plastic. You collect leftover sheets and trim waste. Factories melt and reuse these pieces. Recycling saves money and helps the environment.

Plastic warps or cracks if you heat it unevenly or cool it too fast. You should set the right temperature and cooling time. Using sheets with even thickness helps stop these problems.

You wear gloves and safety glasses. Keep your hands away from hot surfaces. Check emergency stops before you start. Follow safety signs and instructions. Safety keeps everyone protected.