Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

You can use pressure forming to shape hot plastic sheets. Air pressure helps push the plastic into detailed molds. This process uses both vacuum and air pressure. It gives you sharper and more exact results than older ways. Many companies pick pressure forming because it makes high-quality parts. You can also mold in color. It is easier to put together parts made this way. Pressure forming works well for making a small or medium number of parts. It helps you make complex parts for less money.

Tip: Pressure forming gives sharp details and strong parts. It is a smart choice for many industries.

| Benefit | Description |

|---|---|

| Quality of Pressure Forming | Makes high-quality parts in the molding process. |

| Option to Mold in Color | Lets you choose colors for your design. |

| Ability to Create Multi-Part Assemblies | Makes it easy to put together complex parts. |

| Cost Advantages at Low- to Mid-Volumes | Saves money when making fewer parts. |

Pressure forming uses air pressure to shape plastic parts. It is great for industries that need sharp edges and tricky shapes. This method lets you mold color into the part. Designers can change how products look without painting them. Pressure forming saves money for small or medium batches. It costs less for tools and materials than other ways. The process makes parts with smooth surfaces and strong bodies. This is good for medical, car, and airplane uses. You need to control the temperature well. Extra steps after forming help get the best results.

Pressure forming is a special way to shape plastic. It uses air pressure and vacuum to form plastic sheets in molds. The process pushes plastic into every part of the mold. This makes parts with lots of detail. Pressure forming does not change settings during production like injection molding. You need to use the same settings and materials each time. After forming, you might measure and trim the parts. This helps them fit just right.

| Aspect | Description |

|---|---|

| Definition | Pressure forming is an open-loop process. It needs the same inputs as before. |

| Process Characteristics | You must measure parts often. You also trim and mill the back to make them fit. |

| Comparison with Injection Molding | Injection molding changes itself during production. Pressure forming needs steady input ranges. |

Here are the main steps for pressure forming:

Heating: First, heat a plastic sheet until it gets soft.

Molding: Next, put the hot sheet over a mold with details.

Applying Pressure: Use air pressure to press the plastic into the mold. Sometimes, the pressure goes over 100 PSI. This is much more than vacuum forming. It gives sharper lines and textures.

Cooling: Let the plastic cool so it keeps its new shape.

Trimming and Finishing: Cut off extra plastic and smooth the edges.

Tip: Pressure forming uses much more pressure than vacuum forming. This helps make parts with deep textures and sharp lines.

Pressure forming has many good points. You can make parts with tricky shapes and sharp edges. You can use thick plastic sheets, so parts are strong. This process works well for big parts. Many industries use pressure forming.

| Advantage | Description |

|---|---|

| Design Capabilities | You can make parts with hard shapes, undercuts, and cool textures. |

| Cost-Effectiveness | You save money on tools, especially for big parts. |

| Lightweight Materials | The parts are light, so they are easy to move and use. |

| Surface Detail | You get sharp lines and textures, sometimes better than injection molding. |

| Versatility of Materials | You can choose from many plastics to fit your needs. |

Pressure forming is great for parts that need to look nice and have sharp features.

It is a cheaper way to get detailed plastic parts if you do not need a lot of them.

Pressure forming lets you make parts with lots of detail. High air pressure pushes the plastic deep into the mold. This helps show off small features on the part. You can see fine lines, logos, and patterns very clearly. Many industries use this process for parts that need tight fits and exact textures.

Here is a table that shows how different forming techniques handle detail and texture:

| Technique | Level of Detail and Texture |

|---|---|

| Pressure Forming | Gives more detail and texture. It can copy tiny mold details and gives a fancy finish. |

| Vacuum Forming | Does not give as much detail as pressure forming. |

Pressure forming works for parts that need to look good and work well.

This process is good for products that need a close fit.

You can make detailed shapes, undercuts, and sharp corners in one step.

Note: You can change the tool surface to control the texture on your parts. You can even add tiny patterns to make your product look and work better.

Pressure forming is great for sharp edges and clear shapes. The extra air pressure helps the plastic fill every part of the mold. This gives you crisp lines and corners. You can make parts with undercuts and tricky shapes that are hard with other methods.

You can make parts with lots of detail and complex shapes.

High pressure makes sharp edges and deep textures possible.

You can design parts that look like injection molded items.

But pressure forming does have some limits. If you try to make very tricky undercuts, it may not work as well as injection molding. The process stretches the plastic sheet, so deep undercuts may not be as exact. Injection molding is better for these shapes and can make more detailed designs without extra steps.

Pressure forming gives a nice surface finish. It is usually better than vacuum forming but not as smooth as injection molding. This makes pressure forming a good choice for big parts that need to look clean and have sharp details.

To get the best surface finish, follow these steps after forming:

Initial Assessment: Look at the part for any flaws.

Coarse Sanding: Use rough sandpaper to fix big problems.

Intermediate Sanding: Use medium sandpaper to smooth it more.

Fine Sanding: Use fine sandpaper to make it shiny.

Dust Removal: Clean the part to get rid of dust.

Even Pressure: Sand with steady pressure to keep it even.

Directional Sanding: Sand in one direction to hide scratches.

Gradual Progression: Use finer sandpaper step by step for the smoothest finish.

Tip: Take your time with each finishing step to get a pro look. This helps your parts look great and meet high standards.

Pressure forming and vacuum forming are different in many ways. Vacuum forming uses suction to shape hot plastic over a mold. This way is good for simple shapes and big parts. It costs less to make the tools, so it is good for small batches or test pieces. But vacuum forming cannot make sharp details or use thick plastic like pressure forming can.

Here is a table to show how they are not the same:

| Aspect | Vacuum Forming | Pressure Forming |

|---|---|---|

| Cost | Usually cheaper tools | Tools cost more at first |

| Production Speed | Quicker for small and medium batches | Best for making more parts |

| Part Quality | Good for big, simple shapes | Makes parts with sharp edges and fine details |

Vacuum forming is best if you want to spend less and do not need lots of detail. Pressure forming is better for sharp edges, deep textures, or thick plastic.

Injection molding is another way to make plastic parts. Melted plastic goes into a metal mold with high pressure. This gives very exact shapes and smooth surfaces. It is great for making thousands of the same part. The molds cost a lot, but each part is cheaper if you make many.

| Method | Tooling Costs | Production Volume Suitability |

|---|---|---|

| Injection Molding | Expensive because molds are complex | Good for making lots of parts |

| Thermoforming | Cheaper and faster to make molds | Better for fewer, bigger parts |

Injection molding can make parts with very tight fits, as close as ±0.025mm. You get the best accuracy if you need a lot of parts.

If you want to pay less for tools and do not need super exact parts, pressure forming is a good pick. You can make big, detailed parts without spending a lot at the start.

Every method has good and bad sides. Here is a quick look at pressure forming:

| Advantages | Disadvantages |

|---|---|

| Efficiency | High Start-up Costs |

| Material Utilization | Porosity Issues |

| Strength and Durability | Limited Heat Treatment |

Pressure forming saves time because it is faster to get started.

You use less material, so you save money.

The parts are strong and last a long time.

It costs more to start than vacuum forming.

Sometimes, small holes can make the part look or work worse.

Some heat treatments do not work because of these holes.

Tip: Pick pressure forming if you want sharp details, strong parts, and a good balance of cost and quality.

Pressure forming is used in many industries. Companies pick this process to make strong, detailed plastic parts. It is important where sharp edges and tough materials are needed. Some industries that use pressure forming a lot are:

Aerospace

Automotive

Healthcare

Telecommunication

Commercial air travel

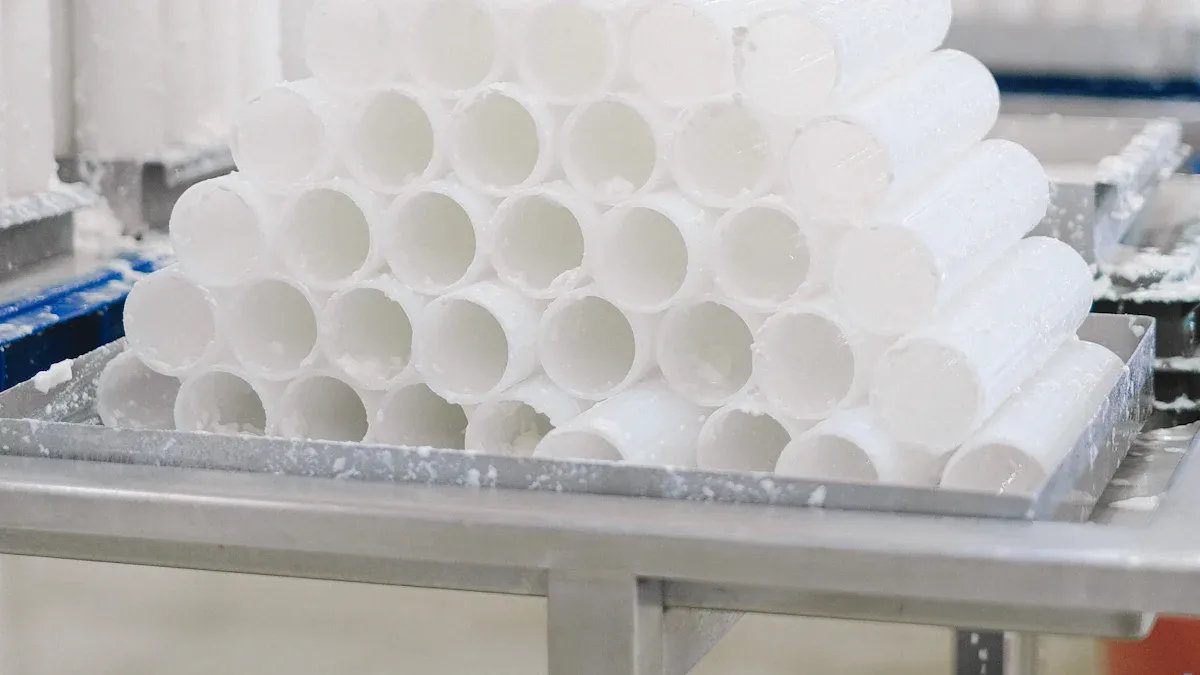

Water filtration

Medical and transportation fields use pressure forming for their products. These fields need parts that look nice and work well.

Pressure forming lets you make many different products. You get sharp details and thick materials, so parts last longer and look better. Here are some products that use this process:

| Product Type |

|---|

| Plastic bathtubs |

| Plastic utensils |

| Office equipment |

| Medical devices and parts |

| Exterior panels with gauges |

| Housings for electrical devices |

| User-facing parts like doors |

In the medical field, pressure formed enclosures protect devices. In transportation, custom plastic parts help vehicles work better. Pressure forming is also good for prototyping. You can test new ideas before making lots of parts.

| Industry | Product Type | Description |

|---|---|---|

| Medical | Medical Device Enclosures | Pressure formed plastic is often the best choice for making enclosures for medical devices. |

| Transportation | Custom Plastic Parts | Advanced pressure forming makes high-quality custom plastic parts for many transportation uses. |

You want your pressure forming results to look sharp and last a long time. Try these tips to avoid mistakes:

Use the right forming temperature. If the temperature is wrong, the material may not form right.

Control the forming speed and cooling time. If you go too fast, you might get warping or other problems.

Do not skip post-processing. Trimming and finishing help your parts fit and look better.

Tip: Plan carefully during prototyping to find problems early. You save time and money by fixing things before making many parts.

Check each step to get the best results. Pay attention to details, and your parts will meet high standards.

You can make plastic parts easier with pressure forming. This way is fast and uses cheap molds. You can also recycle the extra plastic you cut off. Many industries use this method for sharp, good-looking parts.

You spend less money on tools and materials.

You can make big or medium parts fast.

| Industry Sector | Applications |

|---|---|

| Medical Equipment | Blood tests, x-ray machines |

| Industrial Applications | Lift trucks, inside truck parts |

| Retail | Kiosks, store displays |

| Recreation Equipment | Snowmobiles, ATVs, jet skis |

If you want to begin, look at different suppliers. Make sure you know what you need. Compare prices and pick a partner who fits your budget and quality needs.

You can use ABS, polycarbonate, polystyrene, and acrylic. These plastics get soft when heated and keep sharp shapes. Pick the plastic that works best for your part.

Pressure forming uses more air pressure than vacuum forming. This makes sharper edges and deeper textures. Vacuum forming is better for simple shapes. Pressure forming gives more detail.

Yes, you can add color during pressure forming. Choose colored plastic sheets before you start. This means you do not have to paint the parts later.

Pressure forming works well for making prototypes. You can test your design with real plastic. This helps you see how the part looks and fits before making a lot.

Pressure forming is used in medical, automotive, and aerospace fields. Companies use it to make strong and detailed parts. It is also used for retail and recreation equipment.